Factors like seismic events and strong forklift or material handling equipment impact can quickly overturn an unstable or improperly installed single row pallet racking system. To prevent this from happening in your facility and potentially damaging products or injuring your employees, you need to follow the basic height-to-depth ratio rule of thumb during the pallet rack installation process.

What Is Height-to-Depth Ratio in Pallet Racking Systems?

Height-to-depth ratio indicates the length or height of the pallet rack in relation to the width of the base. The height and base width have to complement one another in order to make for a stable and virtually indestructible pallet racking system.

If the values of the height and the width of the base are the same or the value of the base is greater than the value of the height, then this makes for a very stable pallet racking system. However, if the value of the height exceeds the value of the base width, then the pallet racking system is likely to be very unstable and more prone to overturning even at the slightest pressure or impact application.

Warehouses, distribution centers, manufacturing facilities, and other types of industrial facilities where large sums of products are stored or moved rely heavily on stable and durable pallet racking system installation and maintenance. Height-to-depth ratio accuracy can help reduce the risk of pallet racks toppling over unexpectedly and causing structural or product damage as well as injuring warehouse workers.

How to Calculate Height-to-Depth Ratio for Pallet Racking Systems

The formula for calculating the height to depth width ratio for any given pallet racking system is pretty simple. But it requires the utmost precise measurements of both the height and width of the unit.

Start by carefully measuring the height of the unit from floor to the top of the highest level beam. Double check your measurements to make sure they’re accurate. To get the value of the depth, measure the width of the base along the floor from the exterior of the column in the front to the exterior of the column in the back. Make sure those measurements are also accurate.

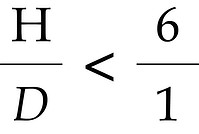

Once you have the pallet rack specifications down pat, use the following formula to calculate the height-to-depth ratio of the unit.

H stands for height and D stands for depth. Divide the height of the structure by the depth of the structure. For optimal stability, the value of the height divided by the depth of the frame should equal 6:1 or lower. If the height-to-depth ratio exceeds 6:1, then you’re going to need stronger reinforcements to secure the entire framework in place and reduce the risk of overturn at the slightest bit of impact.

Why Is Height-to-Depth Ratio Important in Pallet Rack Installation?

Accurate pallet rack specifications, especially when it comes to height-to-depth ratio, are important because they guarantee the stability and maximize the weight capacity and distribution of the unit while also reducing the risk of structural failure.

The height-to-depth ratio also indicates what type of stabilization features you’re going to need. If the height-to-depth ratio is less than 6:1, then you can go ahead and use standard stabilizers or anchors to secure the unit in place. However, if the height-to-depth ratio exceeds this value, then you’re going to need special reinforcements like overhead ties to reliably secure it in place and prevent structural overturn.

Tips to Prevent Overturning Pallet Racks

There are a few important steps you can take to completely secure your pallet racking systems in place and prevent them from toppling over due to impact from seismic events or contact with material handling equipment.

Add Anchors

First and foremost, you need to anchor your pallet racks in place or else any small contact or impact could cause them to fall over and the last thing you want is to have a massive liability issue on your hands. Anchors help stabilize the framework of your pallet racks and keep them steady. Standard anchorage information and recommendations are typically included in your pallet racking system installation manual. However, you should always consult the manufacturer or a professional pallet rack system engineer to ensure that you’re using the right anchors and that they’re correctly installed.

Install Large Base Plates

Base plates are large metal plates that weigh the entire structure down. With the right anchors, base plates can prevent pallet racks from overturning. Large base plates ensure better weight distribution, so be sure to consult an engineer about the proper sizing and anchorage for your pallet racking system.

Add Cross Aisle or Overhead Ties

Cross aisle or overhead ties are designed to connect two parallel beams or frames located at the very top of single row pallet racks to further stabilize the framework and hold it in place during seismic events, material transportation, and other facility operations. These reinforcements are also used for hanging warehouse equipment to protect them from collisions with other structures or pieces of machinery.

What Does It Take to Overturn a Pallet Racking System?

It doesn’t take much to overturn an unstable pallet racking system that hasn’t been properly secured in place. An overturning force of about 350 pounds colliding into the topmost beam of an unstable pallet rack can cause it to topple over. In the logistics industry, that doesn’t amount to a lot of weight considering how heavy standard material handling equipment and product loads can be.

Adhering to the abovementioned overturn prevention tips and consulting with a licensed pallet rack engineer should be enough to avoid an accident.

Canadian Rack Technologies Inc. is a trusted name in the pallet racking industry. We buy and sell new and used pallet racking, industrial storage systems, and warehousing equipment. Our experienced pallet rack technicians can help you determine the accurate height-to-depth ratio for your units and guarantee that you’re using the correct reinforcements to maximize structural integrity, strength, and stamina. Contact us today to learn more.