Choosing the perfect shelving system for your warehouse or business can be a daunting task. With various options available, it’s crucial to find a solution that meets your specific storage requirements. In this blog, we’ll explore the differences between boltless and bolted shelving, helping you make an informed decision.

Industrial shelving systems are essential for organizing and optimizing storage spaces. Whether used in a large warehouse or a small business setting, the right shelving can significantly boost operational efficiency. The decision of boltless vs. bolted shelving requires careful consideration of specific needs and preferences.

Selecting the right system affects your operations, productivity, and costs. A well-organized storage area streamlines your workflow, reduces clutter, and enhances accessibility, simplifying inventory management and order fulfillment.

Understanding Boltless Shelving

Boltless shelving is a popular option for many businesses due to its innovative design and ease of use. Unlike traditional bolted shelving, boltless racks are assembled without the need for nuts, bolts, or screws. Instead, they use an innovative clip type system that allows for a quick and hassle-free setup.

Boltless shelving is versatile and adaptable, making it suitable for a wide range of applications. Commonly found in retail stores, offices, and warehouses, these shelves offer a clean and aesthetically pleasing look, so they’re ideal for settings where presentation matters.

Advantages of boltless shelving:

- Easy assembly and disassembly

- Adjustable shelves

- Versatile and adaptable

- Aesthetically pleasing

Disadvantages of boltless shelving:

- Potential stability issues for heavy loads

- Limited load capacity compared to bolted shelving

Understanding Bolted Shelving

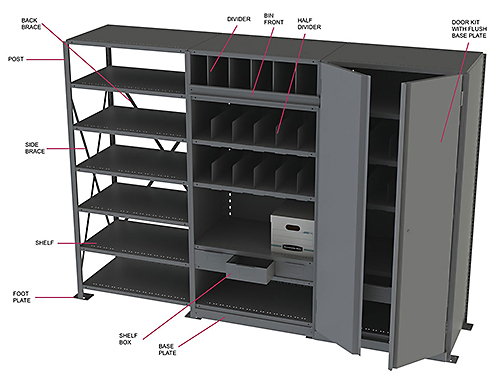

Bolted shelving, on the other hand, relies on a more traditional construction method, using bolts, nuts, and screws to secure the components. While assembly may take longer than boltless shelving, the resulting structure is highly stable and robust.

Bolted shelving is commonly used in industrial settings where strength and durability are critical. From storing heavy machinery parts to managing bulk inventory, bolted shelving is designed to withstand the demands of heavy-duty applications.

Advantages of bolted shelving:

- High load capacity

- Durable and sturdy

- Ideal for heavy-duty storage

Disadvantages of bolted shelving:

- Time-consuming assembly and disassembly

- Less adjustable than boltless shelving

- Generally less aesthetically pleasing

Boltless vs. Bolted Shelving: A Comparison Table

Use this table to consider the unique advantages and disadvantages of each option.

| Feature | Boltless Shelving | Bolted Shelving |

| Assembly | Tool-free, easy assembly | Requires tools and hardware |

| Adjustability | Height-adjustable without tools | Fixed or adjustable with tools |

| Stability | Lighter, less stable | Sturdier, more robust |

| Load Capacity | Moderate | High |

| Durability | Good for moderate loads | Excellent for heavy loads |

| Aesthetics | Sleek and modern | Industrial look |

| Cost | Generally more expensive | Generally less expensive |

Choosing the Right Shelving for Your Needs

To make an informed decision, several factors should be considered when choosing between boltless and bolted shelving:

- Type of Items to Be Stored: Determine the size and weight of the items you plan to store to ensure the shelves can accommodate them safely.

- Weight of Items: Boltless shelving is best suited for lighter loads, while bolted shelving can handle heavier weights with ease.

- Storage Space Available: Consider the dimensions of your storage area to ensure the shelving system fits comfortably.

- Budget: Evaluate your budget to find a shelving solution that provides the best value for your investment.

- Desired Aesthetic: If presentation matters, boltless shelving may be the more visually appealing option.

Discover the Perfect Shelving Solution: Explore Canadian Rack Technologies Today!

Both boltless and bolted shelving offer distinct advantages, and the right choice depends on your specific storage needs. By carefully considering your requirements, you can select the warehouse shelving system that maximizes efficiency and productivity while enhancing the overall functionality of your space.

At Canadian Rack Technologies, we specialize in providing top-of-the-line storage solutions tailored to your unique needs. Whether you’re looking for the convenience of boltless shelving or the durability of bolted shelving, we have the expertise and products to meet your requirements.

Contact us today to learn more and explore our wide range of industrial shelving options.